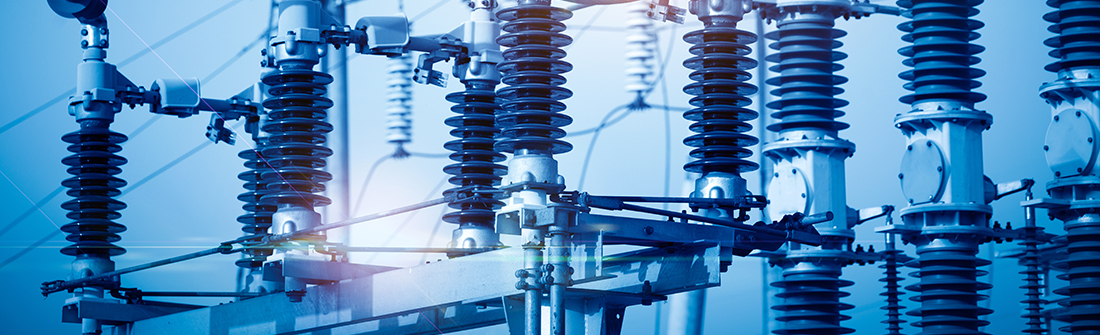

CharCoat IC is a unique room temperature vulcanized (RTV) silicone elastomer formulation specifically developed by CharCoat Passive Fire Protection, Mace Technologies and in collaboration with the Electric Power Research Group of the University of the Witwatersrand for the prevention of pollution flashover of high voltage outdoor insulation.

The exceptional hydrophobicity of CharCoat IC inhibits the formation of continuous moist conductive layers on insulator surfaces. This, in turn, limits the flow of leakage currents thus preventing the creation of dry bands and partial discharges – critical steps in the flashover process.

The superior performance of silicone rubber over other insulating materials in polluted environments is well proven. What makes silicone unique is the fact that, owing to the migration of low molecular weight silanes that exist within the elastomer, the water repellent properties are imparted to contaminants which accumulate on the surface.

The constant water-repellency exhibited by CharCoat IC coated insulators, even in the most severe environments, coupled with silicone’s inherent resistance to degradation by ultra-violet radiation, ozone and most chemicals, combined with the use of specialized fillers to combat power arc damage, enables the material to provide enhanced system reliability over a period of many years.

What Does This Mean?

When Insulators (or other surfaces) are coated correctly with CharCoat IC, there is no leakage of current, the CharCoat IC will repel pollutants due to its superb hydrophobicity (hydrophobicity is the physical property of a molecule (known as a hydrophobe) that is seemingly repelled from a mass of water. ) and the insulator will perform at its maximum capacity! CharCoat IC, with good maintenance will continue to repel pollutants up to and over 20